No-one is making such a far-fetched proposal, but similar thinking has been used to justify halting the railway electrification programme in England and Wales.

Self-powered trains on the UK rail network run on diesel. Diesel engines and associated equipment are constrained by space and weight limitations that in some cases can reduce passenger-carrying capacity. For example, the two power cars that produce 3.3MW to run the world’s fastest diesel train, Britain’s HST, constitute 15% of the train’s length. Furthermore, a train’s traction power is less than that produced by its engine owing to powertrain inefficiencies, the need to power auxiliaries, such as compressors, and the train’s hotel load.

Diesel’s constraints

A further constraint is the British loading gauge, which is about 93% the height and 90% the width of that on the Continent, as shown by the fact that the most powerful British and European freight locomotives are respectively of 2.75MW and 3.2MW.

While a diesel locomotive’s power is constrained by space and allowable axle load, an electric train’s power is limited by the 300A maximum current that can be fed from the overhead line through the moving pantograph. Hence, at its nominal system voltage of 25kV AC, the overhead line system can deliver about 7.5MW.

A Class 92 electric freight locomotive has a maximum traction power of 5MW, as does a nine-car electric Pendolino train running at up to 125mph between London and Glasgow. The overhead line also supplies about the extra 1MW that this train requires for its auxiliary machines and hotel load.

The Pendolino

Electric trains also have lower fuel costs, as generating plant is more efficient than a small diesel with a highly variable operating cycle. Moreover, they can offer zero-carbon traction if their electricity is generated from renewables as is the case in the Netherlands. The ability of electric trains to recover braking energy and feed it back into wire offers further efficiencies. Self-powered trains generally cannot store the huge amount of braking energy, the exception being medium-powered battery hybrid trains of which there are very few.

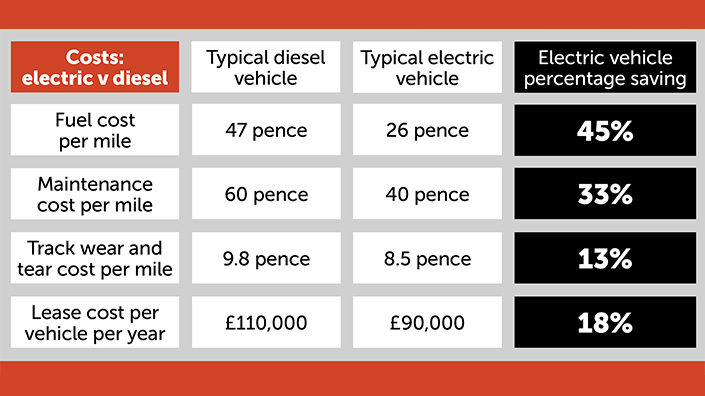

As well as being more powerful and cheaper to run, electric trains are lighter with few moving parts. So they do less damage to the track, and are cheaper to maintain and acquire. These savings are quantified in the table below, which uses data from Network Rail’s 2009 electrification route utilisation strategy.

Electrification resumes

Electrification resumes

Although electrification offers significant benefits, it requires hundreds of millions of pounds to erect overhead line equipment, carry out infrastructure work for the electrical clearances, and to provide power supplies. For this reason, the government has often been reluctant to invest in electrification and so since the 1950s it has been done on a boom-or-bust basis.

In 2010, the project to reopen the Airdrie to Bathgate line also electrified 106 single-track kilometres (stk) to extend the Glasgow suburban electrification network to Edinburgh. This was Britain’s first significant electrification since the 1994 Heathrow and Leeds North West schemes.

After this long gap, Airdrie to Bathgate was to be the first of many new schemes as the government had accepted the benefits of electrification. Between 2009 and 2012, it announced electrification of the Great Western main line, North Western lines, South Wales main line, Midland main line, Electric Spine, Crossrail, Gospel Oak to Barking line and West Midlands suburban lines. In addition, the Scottish government was funding various schemes. These electrification programmes totalled more than 2,000 stk.

Over-budget schemes

The Great Western electrification programme started in 2010 and was expected to cost £1bn. By 2016, its cost had risen to £2.8bn. Other schemes were also significantly over budget. In 2017 the Midland main line, Swansea and Windermere schemes were cancelled.

In the circumstances this was understandable, yet the government announcement of the cancelled schemes did not mention cost. Instead, the House of Commons was advised that “rail technology is advancing quickly” and that bi-mode train technology meant that journeys could be improved without the need for electrification work.

The bi-mode trains mentioned in this announcement have both electric traction and diesel engines that are cleverly packaged so as not to encroach on the passenger area. These trains can usefully provide through journeys to locations beyond the electrified network where it is difficult to justify electrification, for example from London to Penzance.

However, it is wrong to use these trains as an excuse not to electrify. In diesel mode they suffer from the same cost and carbon disadvantages as diesel-only trains. For the reasons mentioned above, when in diesel mode they only have about 60% of the traction power of their electric mode. Hence, they lack the speed and acceleration needed to improve services.

Nevertheless, it is understandable why the government should have lost faith in electrification. If there is to be any more, the industry must demonstrate that it has learned lessons from the Great Western project and that it can deliver electrification at an affordable cost. Fortunately, the Electrification Cost Challenge report recently published by the Railway Industry Association (RIA) does just this. This report details the failings of the Great Western project, which cost £2.8m per stk. These included over-long mast foundation piles, the design of which ignored previous practice, which has now been incorporated in a new standard. The report noted that a cause of these failings was the industry having to mobilise to deliver 2,000 stk in five years when there had been no electrification for 15 years.

Scotland gets it right

Unlike Westminster, the Scottish government is committed to electrification and has funded a rolling programme of seven schemes over the past 10 years totalling 500 stk. These have delivered electrification at £1m to £1.5m per stk. The RIA report provides details of best practice in Scotland, where it considers a rolling programme has enabled lessons to be passed from one project to the next. The report also shows that in Germany a 50-year rolling programme has reduced costs to less than £1m per stk.

Last year, the then transport minister, Jo Johnson, called for the industry to reduce emissions by developing new traction technologies to enable all diesel-only trains to be off the tracks by 2040. With electric traction powering 72% of the UK passenger fleet, this is already the case on many routes. As previously reported, hydrogen trains are one solution for non-electrified lines, although they are unsuitable for busy routes that require high speed and acceleration (see “Could hydrogen trains be the future of rail?,” Professional Engineering No 7, 2018).

On such routes, electrification is the only method of traction that can deliver the required environmental and passenger benefits. However, this requires the government to accept the need for a rolling electrification programme and for the industry to deliver it at an affordable cost.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.