The world’s leading niobium anodes for Li-ion batteries

→ SAFER → FASTER → LONGER

Echion’s XNO® niobium-based anode material enables lithium-ion batteries to fast charge safely in less than 10 minutes, with high energy density and a cycle life of more than 10,000 cycles.

Electrifying heavy-duty applications

Echion’s battery anode materials deliver exceptionally long cycle life, superfast charging capability, and outstanding safety. This leads to uniquely high operational efficiencies and record low total cost of ownership, which enables end users to sustainably electrify heavy duty transport and industrial applications.

These include rail, high-power off-road vehicles, high-utilisation fleets of trucks, buses, or delivery vans, mining equipment, high-performance hybrids, motorsports, and many more applications requiring outstanding performance.

Materials and cells available now

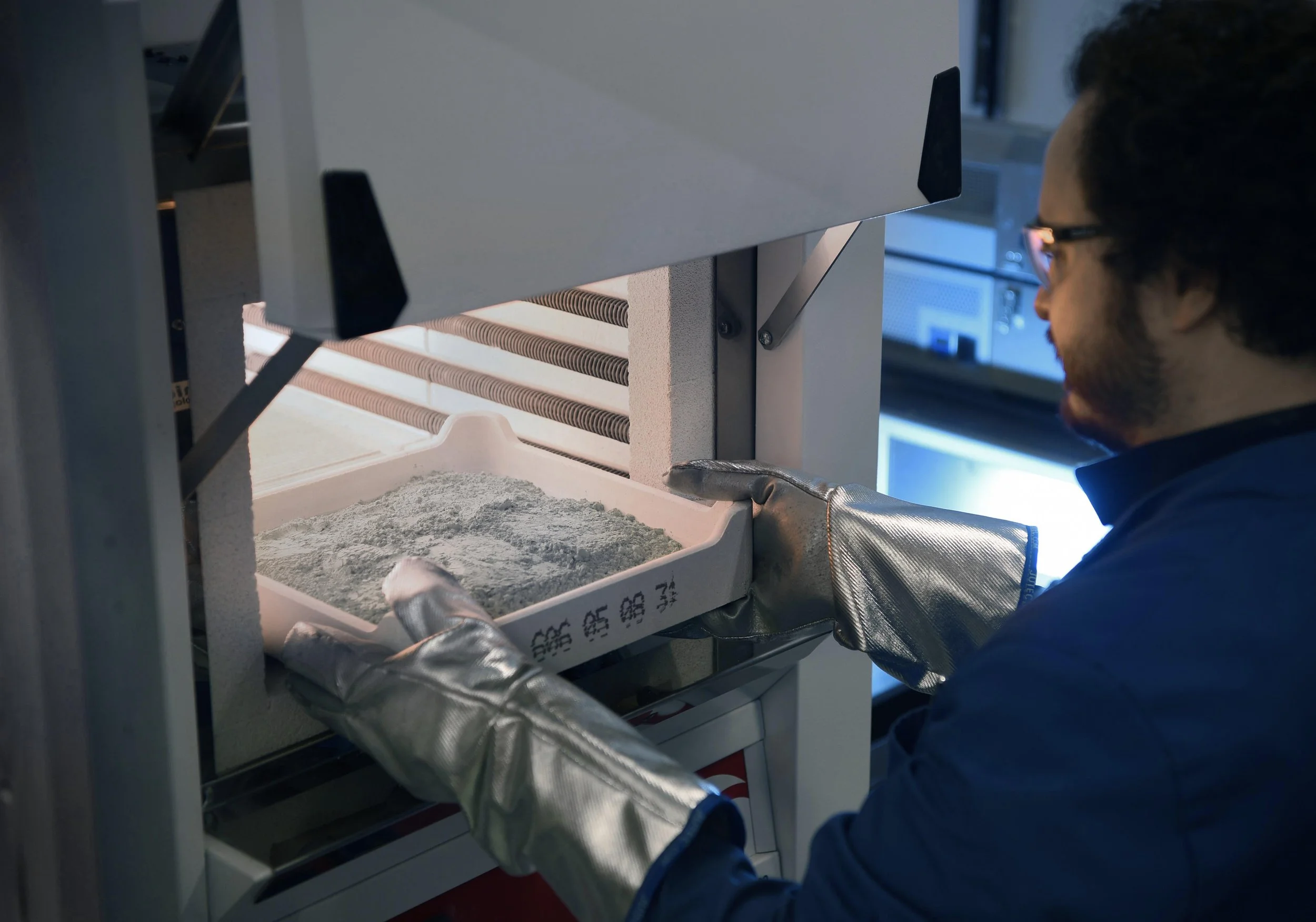

Our business model is to supply XNO® anode active material to cell manufacturers. We will reach 2,000 tonne/year production capacity by 2024.

We also supply low volumes of demonstrator cells to Tier 1s and OEMs for evaluation, before connecting them with our network of cell manufacturers.

Our team of expert scientists and engineers is here to support throughout your product development cycle. Get in touch to join our vision for improved commercial and industrial e-mobility.

Unique XNO®

technology

Echion spun out of Cambridge University in 2017. Our XNO® materials are based on proprietary mixed niobium oxide compositions and microparticle designs protected by multiple international patent families, 6 of which have granted patents.

The unique crystal structures of our materials have been engineered to enable the intercalation of lithium ions with exceptionally fast diffusion coefficients, safe electrochemical potential above SEI formation, and minimal volume expansion.

Work with us

We can help you fast track the assessment of our material using our expertise in cell performance and our partnerships in the battery supply chain. This support will help you to achieve credible results and a successful transition to a differentiated material that will excite your customers. We will be with you every step of the way.

Our world class customer service will help to reduce the commitment in time and resources required to make the necessary evaluation.

Frequently asked questions

-

Active anode materials are essential for the performance of lithium-ion batteries. They play a significant role in storing and releasing lithium ions during charging and discharging cycles. These materials have a direct impact on the fast-charging capability, battery lifetime, safety, and energy density.

When it comes to fast-charging, the choice of active anode material influences the safe charging rate of the battery. Typically, an anode material with a high lithium ion diffusion rate, and high ionic conductivity will often result in better fast-charging performance.

Battery lifetime is another aspect affected by active anode materials. When lithium ions are stored and released from the anode material, a stable anode material will see minimal irreversible mechanical and chemical changes occurring, leading to high cycle life. The selection of anode chemistry, and its crystal structure greatly influence this stability.

With regards to safety, a suitable anode material can mitigate safety concerns and maintain stable battery performance in a range of external conditions. Typically, high safety is achieved if the anode prevents the formation of lithium dendrites and can maintain cell temperatures within the safe working ranges of the battery electrolyte under catastrophic failure conditions (e.g. puncture, crushing, bending).

Finally, energy density, which determines the amount of energy stored per unit volume or weight, is significantly influenced by active anode materials. Anode materials with higher energy storage capabilities can enhance the overall energy density of lithium-ion batteries.

-

Most of today’s lithium-ion batteries use graphite as an anode material, some of which is synthetically produced. Other anode materials used in battery production are hard carbon, silicon, graphene, lithium titanate (LTO) and of course niobium.

Graphite is the most common anode material for lithium ion batteries today and its performance, handling requirements and cost is well understood.. It also delivers high cell energy density due to its relatively high specific capacity. Often, graphite is mixed with other materials such as silicon to further enhance the specific capacity and thus cell energy density.

When fast-charging is required, LTO is considered the safest alternative, however its lower specific capacity leads to lower energy densities at cell level. Though known to have a higher upfront cost vs. graphite, the long cycle life enabled by LTO tends to deliver a lower total cost of ownership (TCO) vs. graphite in high-duty cycle applications.

When processed as an anode material, niobium-provides excellent energy density, safe fast charge capability and long cycle life. One such niobium anode material, XNO® is discussed further in these FAQs.

-

Different anode materials have different attributes which will need to be assessed against the specific requirements and application of the battery. For example, if upfront cost and energy density is the primary consideration, then graphite might be the most sensible solution.

However, if the total cost of ownership, where the cost of the battery is assessed over its lifetime, and the improvement in the operational efficiency (i.e. productivity) of the vehicle or equipment are important, then anodes which deliver fast-charging and long cycle life are typically a better choice.

The short answer is, there is compromise and trade-off with all battery material selection and understanding the performance criteria of the material and what it will be required to do will be a deciding factor.

-

Niobium was identified in the 1980’s as a potential anode material for lithium ion batteries. Recently, niobium has seens commercial uptake in lithium ion battery cathodes as a dopant, and as a primary material for use in lithium ion battery anode active materials.

Niobium is particularly advantageous in lithium ion battery anode active materials as:

It has a two-electron redox process (Nb5+ to Nb3+) offering the following benefits:

• High specific capacities at moderate operating voltages (~1.6 V)

• Key safety/lifetime advantages

• Abundant, non-toxic, and environmentally sustainable to source

• Greater price stability than other battery feedstocks

-

Approximately 80% of the world’s niobium is found and mined in Brazil, with smaller deposits found in Canada, the United States, Europe and Australia.

In comparison to other battery materials, such as cobalt and tungsten, niobium is not rare, though it has been identified as a critical material to support the growth of green and renewable technologies.

Niobium has been used for many years in steel production with global market of ~110,000 MT/y and while its use is expected to rise as it is deployed in battery technology, the stability of supply is not expected to change.

-

XNO® or mixed niobium oxide is Echion’s proprietary active anode material for lithium ion batteries. XNO® delivers the battery performance that the heavy duty and high-duty cycle transport sectors require.

Echion has developed its XNO® anode material through significant optimisation of composition, structure, manufacturing process, and electrochemical properties. XNO® has been designed to offer the best combination of cell performance characteristics and electrode processability (i.e. a ‘drop in’ material for use on existing battery manufacturing lines) and has been scaled up for commercial supply.

Key features of XNO® include:

• Resistant to air, water, heat, with a long shelf-life

• Compatible with both NMP and aqueous electrode preparation methods

• Compatible with a range of cathode materials (NMC, NCA, LNMO, etc)

• High electrode density/low porosity achievable (>3 g/cm3)

• Minimal gas generation during cell formation

• High stability, enabling long cycle life

• Low carbon emissions involved in production (~2.5x lower than LTO)

• Recoverable at end-of-life

• Non-toxic

-

A majority of lithium-ion batteries today utilise cathode and anode chemistries optimised for the passenger EV market.

The operational differences between passenger EVs and heavy-duty industrial markets are such that applying passenger EV batteries to such applications results in a large number of cost and performance trade-offs.

Typically, heavy-duty industrial applications greatly benefit from fast charging, long cycle life and energy density to deliver efficient operational performance, plus exceptional safety because of the nature of their use. These are the performances enabled by Echion’s XNO®.

-

A key benefit of XNO® is that it offers the highest energy densities in lithium-ion cells, under fast-charging conditions.

The limitation of Graphite is that the material becomes less efficient in fast-charging conditions, leading to a drop in energy density, not to mention less safe as well, due to the closeness of its electropotential vs. Li+.

Furthermore, XNO® has been demonstrated to match LTO in cycle life in these high power/fast-charging conditions.